TCG Digital

and Linde

Improving EBIT for your process plants with AI-powered optimization and automation solutions

Webinar

Optimizing Processes & Reducing OPEX

with AI-Plant Control

Witness how AOPS™ AIPC by Linde, powered by mcube™, is building autonomous, self-optimizing plants with adaptive, real-time intelligence—driving higher reliability, yield, and efficiency.

Nov 18, 2025 | 10:00–10:45 AM CST

- Plant-wide outcomes!

Top Process Plant Challenges - Straight from the Front Lines

Site Manager

How can I improve EBIT for my

production site?

Process Engineer

How to maximize product yields and plant efficiency?

Planning Manager

How should I run production with changing product demand and prices?

Maintenance Manager

Operations Manager

APC Engineer

I want to create sustainable advanced automation & optimization for my plant

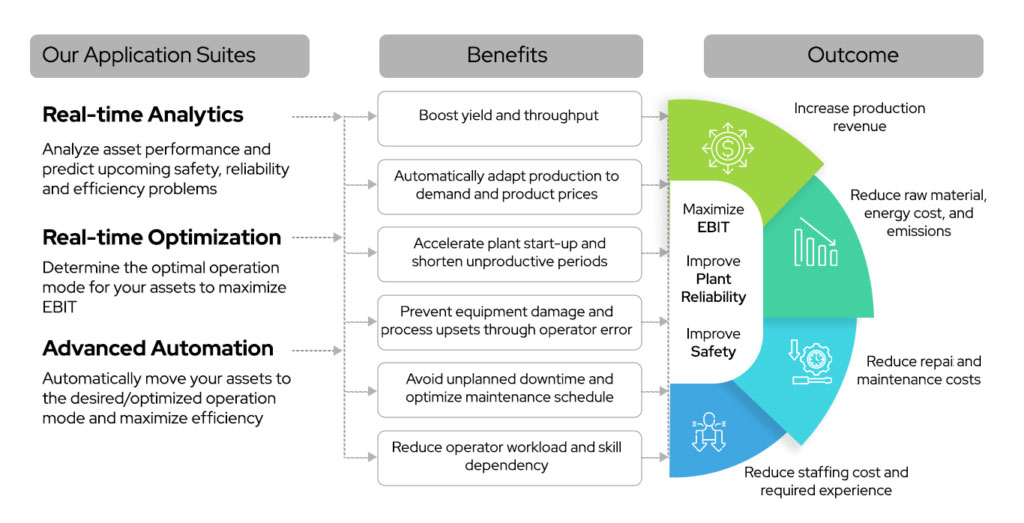

From complex questions to measurable outcome for your assets

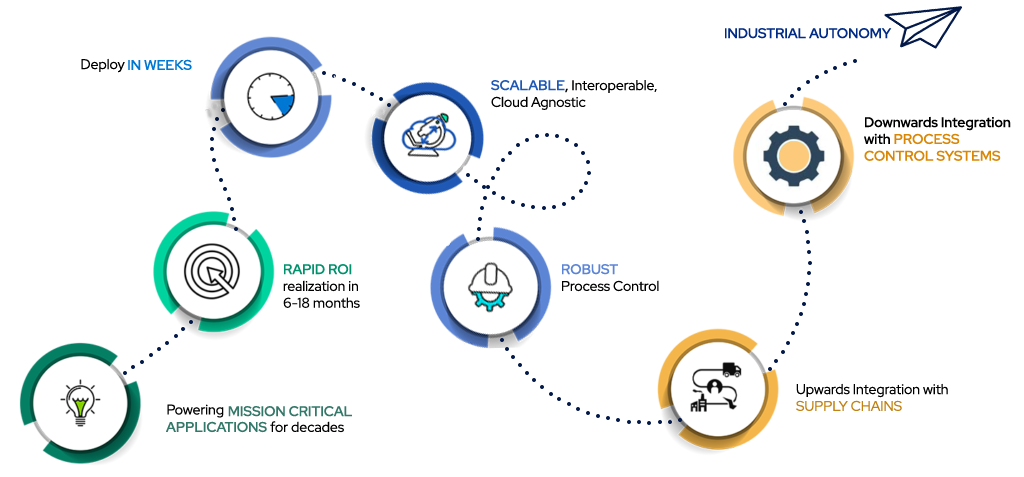

Execution at Scale

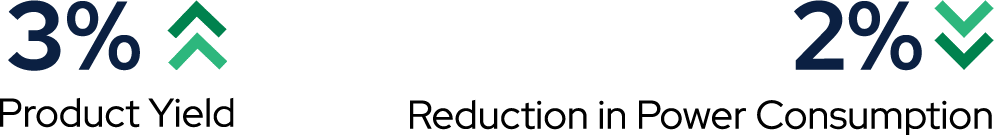

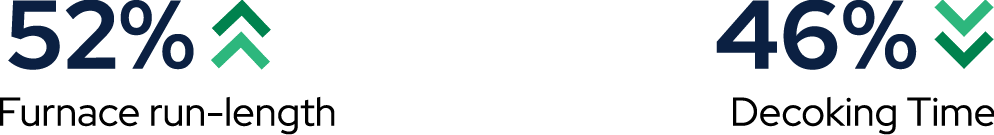

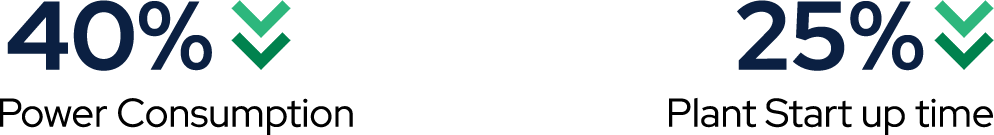

Large Semiconductor Fab in US

Optimizing ultra-high purity electronic gases production through Automatic plant start-up, automatic load changes, and yield optimization

Major steel-works in Germany

Optimizing Oxygen supply and Argon production for constant major demand changes using self-learning AI Plant Control

Ethylene Cracker in US

The key to maximize your asset performance

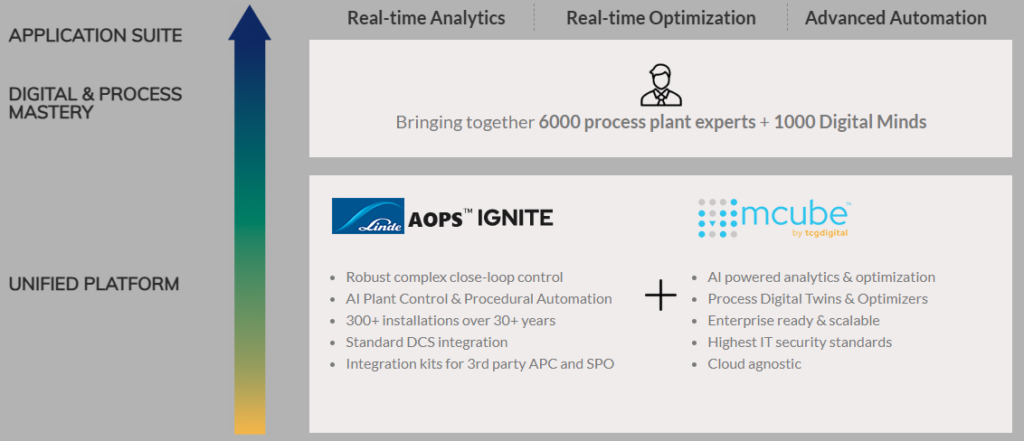

APPLICATION SUITE

DIGITAL & PROCESS MASTERY

UNIFIED PLATFORM

Real-time Analytics

Real-time Optimization

Advanced Automation

- Robust complex close-loop control

- AI Plant Control & Procedural Automation

- 300+ installations over 30+ years

- Standard DCS integration

- Integration kits for 3rd party APC and SPO

- AI powered analytics & optimization

- Process Digital Twins & Optimizers

- Enterprise ready & scalable

- Highest IT security standards

- Cloud agnostic

Smarter Plant Operations at Scale

AI Plant Control

Self-learning and self-optimizing Advanced Process Control

Reliability AI Agent

Identify reasons for process upsets and suggest remedial actions using LLMs

Real-Time Optimizer

Furnace Coil Monitor

Use thermal cameras to monitor coil temperature profiles

Digital Twin/Remote Monitoring

Continuously benchmarking actual asset operations with Process Digital Twins

Plant Finance Cockpit

Get a unified view of your material flow, energy usage, and production in real-time

Automatic Sequence Transition

Intelligent Advanced Procedural Automation